By Tom Linder

We live in interesting times. The specters of overpopulation and climate change are constantly in the headlines. The possible threat of global food shortages as a result of increased food demand and climate change-induced crop failures is hovering just over the horizon. And we keep hearing the same mantra: we can’t go on producing and consuming food the way we used to. So how can humanity get out of this fix with the minimum amount of societal upheaval and ecological disaster? If we are to fundamentally alter our food production practices, we must start with a bird’s-eye view of the basic biophysical principles of our current food production system. We may need to begin making food without photosynthesis.

Fundamentals of food

Why not begin by addressing the two most basic questions of food production and consumption – namely, what is food and why do we need to eat it? Let’s start with the answer to the second question, which is simply that food is anything that provides us with two things: (1) metabolic fuel to power our thinking, our movements and our development from a fertilized egg to an adult individual; (2) building blocks to make, repair and maintain the tissues of our bodies.

So whatever food is, it has to satisfy those two criteria. There are three categories of chemical compounds that do just that: carbohydrates, protein and fats. (We also require vitamins and trace minerals for maintaining our bodies but for simplicity’s sake we will focus on these three major macronutrients.) So all types of food are in essence some configuration of carbohydrates, protein and fats with some micronutrients thrown in for good measure.

All of these three categories of macronutrients can only be made by living organisms. Granted, some organic precursors – like amino acids, which are the building blocks of protein, have been shown to form spontaneously in nature under specific conditions. (This is probably how life started eons ago.) However, the rates of formation are way too slow to sustain contemporary organisms. As animals, our fundamental problem is that we cannot synthesize carbohydrates, proteins or fats directly from inorganic precursors that occur in the surrounding environment. To be more specific, there are three chemical elements that make up the bulk of these macronutrients – carbon (C), nitrogen (N) and sulfur (S), all of which are inaccessible to us in their inorganic forms such as carbon dioxide (CO2) and molecular nitrogen (N2) in the atmosphere as well as dissolved sulfate ions (SO42–) in soils and seawater.

What that means in practice is that another organism first has to assimilate (“fix”) these three elements by incorporating them into their own biomass as carbohydrates, protein and fats before we then can acquire those macronutrients in turn by eating that organism. Pretty much all the carbon that we ingest was originally fixed by photosynthetic organisms like algae and terrestrial plants.

Up until the early 20th century, all the nitrogen that we derived from our food (nearly all in the form of protein) was originally fixed by specialized bacteria in soils and the oceans. Even with the advent of industrial nitrogen fixation (which I will get back to at the end of this post), we still rely on plants, fungi and various microorganisms to convert inorganic nitrogen compounds like ammonia, nitrate and urea into protein. Sulfur, which we also acquire as protein, can be assimilated in its inorganic forms by most organisms with the exception of animals.

The biophysical limits of food production

Now that we have defined what food is, we can start to explore the current limits of global food production capacity based on agriculture, aquaculture etc. What should be clear at this point is that we do not suffer from a shortage of carbon for food production. Consider that in addition to all the CO2 in the atmosphere (more than 700 billion tons), there are essentially limitless reserves of carbonate-containing rocks in the Earth’s crust. What is limiting are edible forms of carbon i.e. those same carbohydrates, proteins and fats I keep mentioning.

So what ultimately limits our global food production capacity is the rate at which inorganic carbon i.e. CO2, is converted into biomass. (An additional problem is that most biomass on the planet is in the form of cellulose that make up wood, leaves and straw. Although cellulose is a carbohydrate, it is not directly accessible to us because we cannot digest it. That is why we keep livestock – they are essentially walking biocatalysts for the conversion of indigestible plant materials like grass and leaves to things we can eat and drink – meat and dairy.)

Taken together, the theoretical upper limit for current global food production practices is determined by the photosynthetic capacity of the entire planet. The total amount of CO2 that is converted into biomass on land and in the seas every year is known as net primary production (or NPP for short), which has been estimated at 105 billion tons of carbon per year. That might sound like a lot (and it is) but all of those 105 billion tons are not accessible to us for food production. At the moment, the proportion of NPP that has already been appropriated by humanity for food, fuel and fiber has been estimated at 25%. Because of the biophysical constraints of contemporary agriculture (i.e. the need for arable land, sunlight, fresh water and favorable climate conditions), it is believed that this number cannot increase much further.

There are some low-tech options out there on how to get around these constraints. One key factor to consider is that photosynthetic activity is not spread uniformly across the surface of the planet. Instead it is concentrated into patches of high rates of photosynthetic carbon fixation, such as grasslands and forests. At the same time there are huge areas where little or no carbon fixation occurs – polar regions, deserts and nutrient-poor zones of the open ocean. If photosynthetic activity can be increased in an area with low natural photosynthetic carbon fixation, this would effectively increase global NPP.

One way to increase photosynthetic activity would be for example by irrigating arid soils for agricultural production, as is done in the Wadi As-Sirhan Basin in Saudi Arabia. The problem of course is that this requires significant amounts of fresh water, which in the case of Saudi Arabia comes from aquifers that eventually will run dry. Another option is to adopt saltwater-tolerant crops, which would enable the expansion agricultural production to coastal regions where the saline soils prohibit the cultivation of conventional crops. You could take this approach one step further and simply move your crops into the oceans by cultivating macroalgae such as kelp. But what other options are there?

The problem with photosynthesis

Since we more or less take for granted that essentially all carbon in our food comes from photosynthesis, the question is rarely asked whether photosynthesis is the optimal way to fix atmospheric CO2 for food production. Photosynthesis has one major drawback, which is its absolute dependence on light energy. Because of this limitation, conventional crop production can only occur in two dimensions.

Proponents of vertical farming will point out that artificial lighting can bypass this problem and allow for stacking of crops in three dimensions. This is true in theory but in practice you quickly run into the issues of cost and energy conversion efficiency. While sunlight falling on a field of crops is essentially “free”, artificial lighting within vertical farming systems will require electricity from an external source. If that electricity comes from solar panels, we must first consider that these panels typically have an efficiency between 10-20%. Add to that the energy conversion efficiency (also known as radiant or “wall-plug” efficiency) when electrical energy goes into an artificial light source and gets converted into light energy.

On top of that you must consider what proportion of the light coming out of the light source that can actually be harvested by the plant for photosynthesis – a spectrum of light is called photosynthetically active radiation (PAR). Granted, recent developments in light-emitting diode (LED) technology look promising with respect to improvements in both energy conversion efficiency and PAR. However, that still leaves the low efficiency of photosynthesis itself, which tends to end up somewhere in the single digits. To cut a long story short, it would be preferable to have a food production system that is not limited to light energy and thereby would not be confined to two dimensions.

There is another perhaps less obvious drawback with a photosynthesis-dependent food production system, which is that the edible biomass (carbohydrates, protein and fats) is often located within the same physical entity – the crop plant itself, as the light-harvesting apparatus. This means that after annual crops such as wheat, corn or soy have been harvested, the fields in which they were grown are suddenly fixing atmospheric CO2 at much lower rates simply because there are few or no plants left in the field to do so. Remember that the key threshold in global food production is the rate at which CO2 is converted to edible biomass.

An empty field is therefore essentially a waste of photosynthetic potential while we wait for the next batch of crops to appear. (This drawback does not apply to perennial food plants such as fruit trees, which retain their full photosynthetic potential after harvest. Of course, some fruit trees will shed their leaves during winter.) So what we would like in the end is a system that also decouples CO2 fixation from the production of edible biomass. This would allow for continuous CO2 fixation independently of the rate at which edible biomass is harvested.

Breaking the NPP barrier

So to re-cap, in order to circumvent the net primary production barrier, we must come up with a way to convert CO2 to edible biomass (carbohydrates, protein and fats) that (1) does not exclusively depend on light energy, and (2) ideally decouples carbon fixation from the generation of biomass edible biomass. As it turns out, this problem was solved more than 50 years ago during the height of the space race.

In a 1964 paper, researchers John Foster and John Litchfield described a continuous CO2-recycling life-support system intended for extended space travel, which would capture the CO2 exhaled by astronauts and convert it into food. This was made possible by an edible bacterium called Cupriavidus necator – also known under a host of older names including Ralstonia eutropha. This bacterium is capable of chemosynthesis, which is a process analogous to photosynthesis but relies on chemical energy carriers instead of light to power CO2 fixation. In the case of the C. necator bacterium, it uses the inherent energy in hydrogen gas (H2) to power the CO2 fixation process.

Hydrogen gas can be generated by electrolysis of water, which is the key to satisfying the first criterion of a non-photosynthetic food production system, as the electrical energy can be provided by any energy source – hydro, wind, geothermal and even nuclear. There might even be a point of using solar power for chemosynthetic production, since it would be possible to place solar panels in a place where conventional agriculture is not possible (like a desert) and then transmit the electrical energy through the power grid to wherever the hydrogen production and subsequent cultivation of edible bacteria takes place. This property also partially satisfies the second criterion of a non-photosynthetic food production system by decoupling one aspect of CO2 fixation (generation of energy) from production of edible biomass. The enzymatic machinery inside the C. necator cell is still required to convert CO2 into biomass. However, this is not a major problem since a C. necator cell growing on a H2/CO2 mixture will divide fairly quickly under optimal conditions – as often as once every three hours. This means that it is possible to harvest half of the C. necator bacteria every three hours indefinitely as long as the bacteria are continuously supplied with a H2/CO2 mixture.

There are in fact some companies today that are trying to commercialize food and feed products derived from H2-dependent chemosynthetic bacteria like C. necator. The Bay Area startup NovoNutrients use industrial CO2 emissions to cultivate an undisclosed microorganism – most likely a H2-dependent chemosynthetic bacterium, which is then processed into a high-protein flour called Novomeal, which is then marketed as aquaculture feed. The Finnish startup Solar Foods are working on a similar process but intends to market the resulting protein product – called Solein, for human consumption rather than be used as animal feed. Solar Foods recently announced that they plan to have Solein for sale in supermarkets by 2021.

The idea of eating protein flour made from bacteria might seem like a novel idea but the concept of edible microorganisms such as bacteria, yeasts and filamentous fungi is in fact quite old. The Aztecs were known to harvest photosynthetic bacteria from Lake Texcoco before the lake was drained following the Spanish conquest (the remaining lake basin is now part of Mexico City). The same kind of photosynthetic bacteria are still harvested today from alkaline lakes in Chad by the indigenous Kanembu people (as described in the video below). In 1902 the Marmite Food Company in the UK launched its now (in)famous sandwich spread made from spent brewer’s yeast. More recently, biomass from the filamentous fungus Fusarium venenatum is used as the main ingredient in Quorn-brand meat imitation products.

Microbial biomass makes a good source of food due to its high protein and vitamin content. Unfortunately, only a small minority of edible microorganisms is capable of chemosynthetic growth like that of C. necator. Most edible microorganisms instead require organic substrates for growth – sugar being the most commonly used substrate for microbial biomass production at present. However, most microorganisms also have the ability to grow using very simple organic compounds like hydrocarbons, alcohols and organic acids.

As it happens, there are a number of hydrocarbons, alcohols and organic acids that can be synthesized directly from CO2 using different chemical and biological processes. This means that rather than edible microorganisms fixing CO2 themselves, the CO2 is fixed in a separate process to produce an organic compound that the edible microorganism can then use for growth. Such a two-step process would satisfy the two criteria for non-photosynthetic food production mentioned previously, namely (1) not being solely reliant on light energy and (2) decoupling carbon fixation from generation of edible biomass.

There are several possible options for how edible microbial biomass could be produced from organic compounds that in turn have been synthesized directly from CO2. I will describe one such example in more detail. Methanol (CH3OH) is the simplest alcohol and can be produced from CO2 by a simple hydrogenation reaction:

CO2 + 3 H2 → CH3OH + H2O

The company Carbon Recycling International runs a factory on Iceland, which produces 4,000 tons of methanol per year by hydrogenating CO2 from emissions that come from a neighboring geothermal power plant. This methanol is intended for use as a drop-in fuel but could also be used to cultivate a wide variety of edible microorganisms. Although methanol is toxic to animals, many microorganisms can grow just fine using methanol as their only source of metabolic carbon. In fact, during the 1970s and 80s, the British company Imperial Chemical Industries developed a high-protein animal feed called Pruteen, which was derived from the edible methanol-assimilating bacterium Methylophilus methylotrophus.

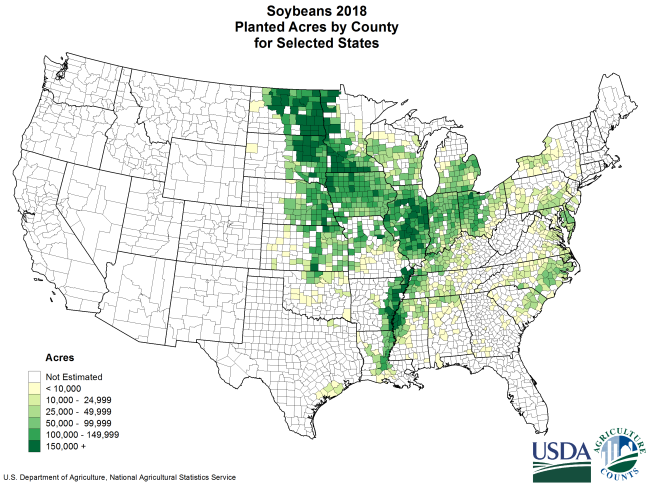

Ultimately Pruteen production was discontinued due to rising methanol prices and competition from cheaper soy-based feeds. Nevertheless, the Pruteen process demonstrated that it was possible to produce edible microbial biomass in significant amounts (50,000-60,000 tons per year) from a single 1,500-m3 bioreactor. I have recently estimated that if the entire US soy production capacity (about 120 million tons per year) was to be replaced with methanol factories and Pruteen-style bioreactors, it would occupy roughly one thousandth of the same land area. However, this estimate does not include energy sources to power the CO2 conversion process. So the land-sparing potential of such a process would depend heavily on the power density of the chosen energy source.

Final big thoughts

What should be clear from the examples of edible chemosynthetic bacteria as well as edible methanol-assimilating bacteria that I presented above is that producing edible microbial biomass from CO2 in a manner that does not require photosynthesis carries with it some pretty significant implications. Microorganisms are typically cultivated in large (10-1000 m3) bioreactors where internal growth conditions (temperature, rate of mixing, supply of air and nutrients etc) are controlled independently of external conditions. This means that edible biomass – food, can be produced anywhere the planet independently of local climate conditions or access to arable land. Suddenly deserts, tundra, underground caves or even the open ocean can become hubs for high-capacity food production.

If global food production capacity is no longer constrained by NPP, the new limits for just how much food humanity can produce per unit time now comes down to energy and money. What will this mean for Earth’s carrying capacity? Will the human population continue to grow if food production is no longer constrained by photosynthesis (and prove Paul Ehrlich wrong again)? If my back-of-the-envelope calculation is correct, will the higher production density of edible microbial biomass enable us to restore a significant proportion of agricultural land to its natural state thereby protecting biodiversity – and perhaps even managing to sequester a big chunk of atmospheric CO2 in the process? It all remains to be seen.

In closing, it might be instructive to compare our current situation with the scarcity of nitrogen fertilizers (manure, nitrate-containing minerals) that faced global agriculture at the end of the 19th century. At the time it seemed as if the global food production system had reached a seemingly insurmountable boundary. Then came the invention of industrial nitrogen fixation by German scientists Fritz Haber and Carl Bosch in the beginning of the 20th century and suddenly humanity was no longer dependent on biological nitrogen fixation. As a result the human population could continue to grow from less than two billion in the year 1900 to 7.7 billion today (and counting). In fact it has been estimated that half of the nitrogen in our bodies now comes from the Haber-Bosch process rather than biological nitrogen fixation.

If humanity can become independent of biological carbon fixation as we did with nitrogen, recent history would suggest that this in itself will not promote stabilization of the global population. Instead the global population is expected to plateau and eventually shrink thanks to falling fertility rates as a consequence of increasing living standards, which allow parents across the globe to choose to have fewer children. So ultimately the challenge of this century (and perhaps the next one as well) will be to feed humanity in a sustainable fashion as it attempts to clear this demographic hurdle. And if you ask me, edible microbes produced independently of photosynthesis would seem like the way to go.

Written by Guest Expert

Tomas (“Tom”) Linder is a microbiologist and molecular geneticist who studies metabolism in microorganisms and has a particular fondness for yeasts. He is based at the Swedish University of Agricultural Sciences in Uppsala, Sweden. Follow Tom on Facebook at Yeast Genomix.